1) Using our SST2000 coating, you will get

- Less than 1% porosity

- 6 to 10 RMS finish

- Coating thickness of .011” to .013”

- Total Indicated Runout of .0004” or better

- 48 Rc or 60 Rc hardness available

- A tough coating that is corrosion and rust resistant and allows for easier cleanup

2) For less severe damage, Sterling Surface Technologies also has the ability to just grind and polish your C I Drum back to a quality finish within OEM specifications.

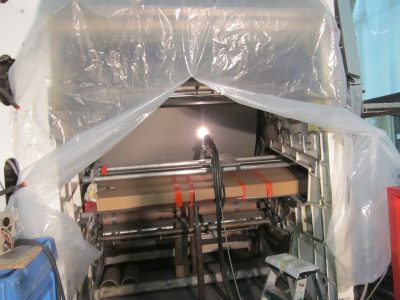

3) For newer gearless /frame style presses, Sterling Surface Technologies has specialized grinding equipment and techniques to provide an error free grind that could be caused by “blending” dimensions from multiple belt grinders.

4) When only a localized Spot repair or patch is required for minor nicks and dings, Sterling’s mobile equipment and technician can be readily dispatched in an efficient and cost effective manner.

5) We also offer a full evaluation and inspection of all of your C I Cylinders.

6) With our 24/7 emergency response, we can mobilize quickly and in most cases, be there to meet your needs within 24 hours.