Sterling uses the highest quality materials available. Our Thermal Spray coating products are manufactured in the USA and comply with FAA and Aerospace standards and specifications.

Our Thermal Spray Process

About our Thermal Spray Process

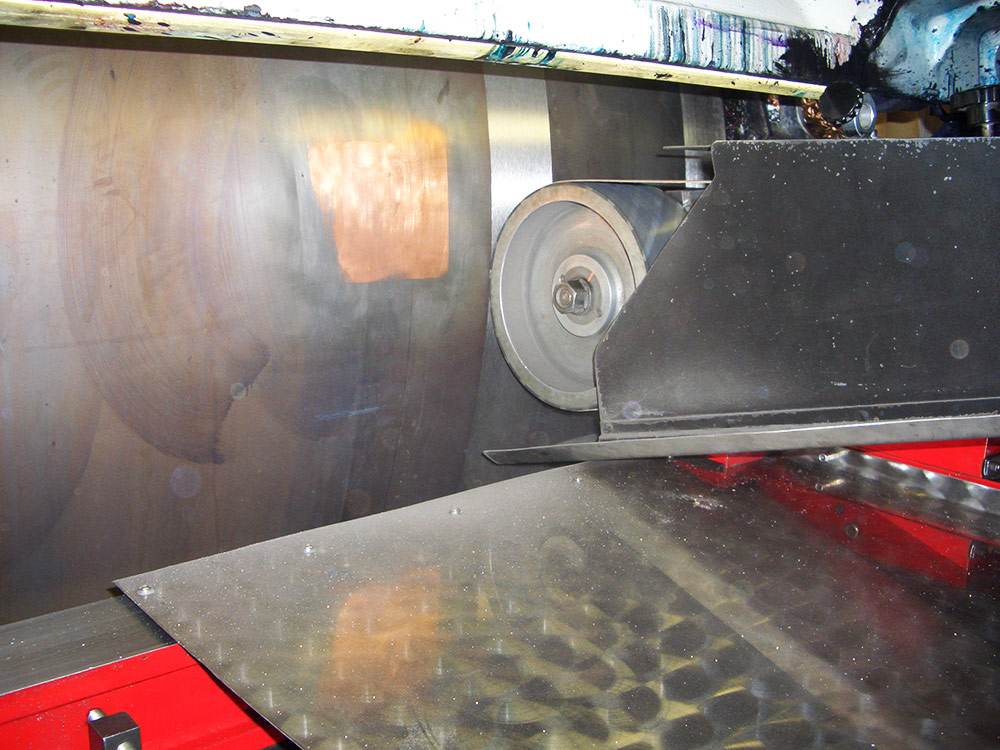

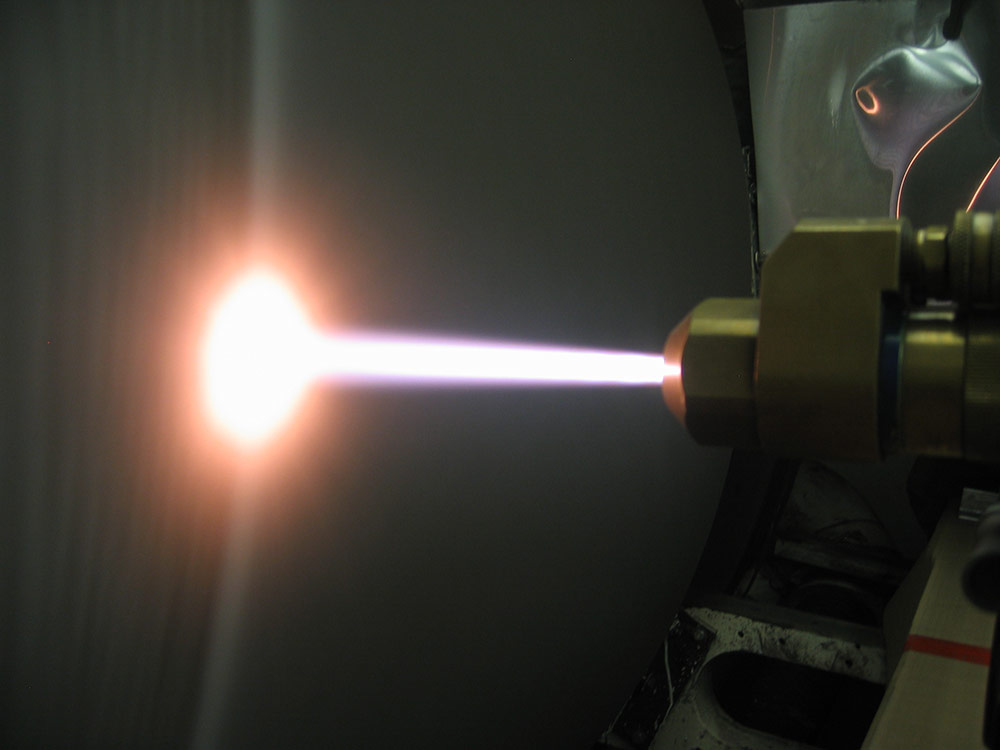

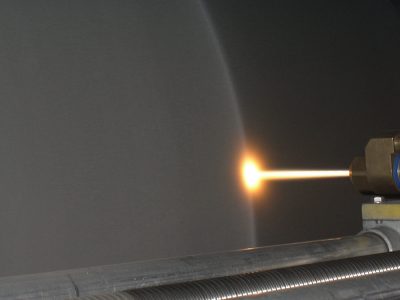

Step 2

Sterling’s SST2000 application process is accomplished using a High Velocity thermal spray technique. The application speed (exceeding 2,700 feet per second) combined with high combustion temperatures of the fuel gases used, result in a sprayed coating which is strong, dense and very low in porosity (<1%).

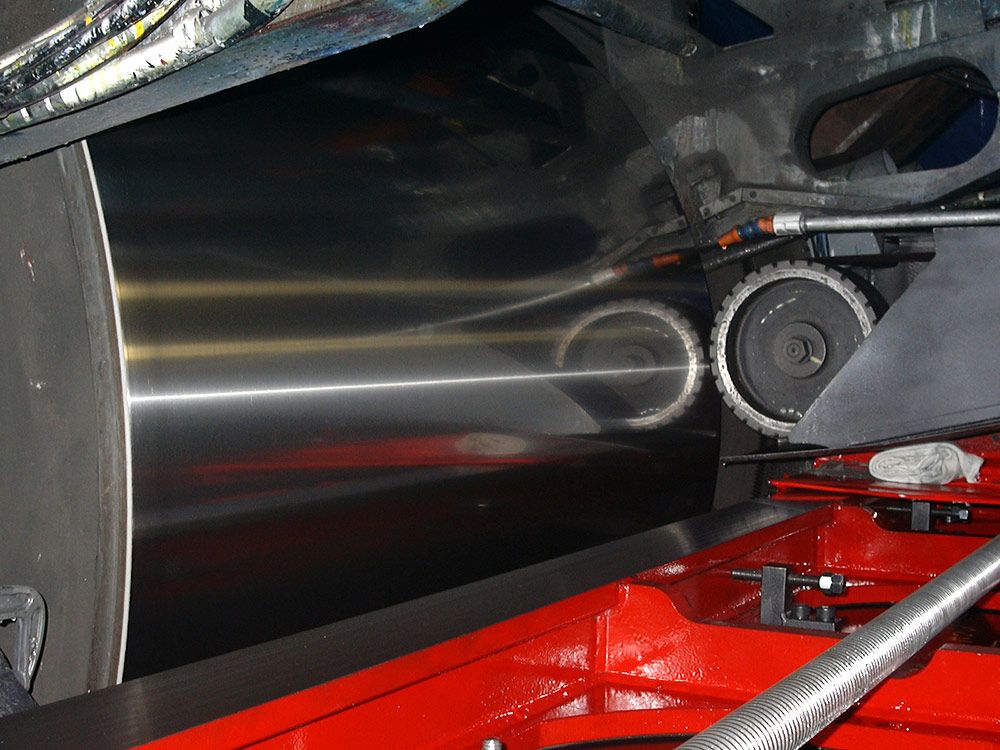

Step 3

Sterling’s rust and corrosion resistant SST-2000 coating offers an exceptional printing surface, resulting in an efficient printing process.

Our process is applied on-site and in manufacturing.

Sterling was able to meet and exceed all of our stringent environmental requirements and also provide the best quality surface to our dual C.I. Cylinder press.

Sterling did an outstanding job in our time of need, the response time and execution was of the highest level.

Sterling is our preferred supplier for C.I. drum repair, we have a great working relationship.

I trust in Sterling and I have no reason to use anyone else.

Sterling is the best around, a top notch company.

Everything went off without a hitch and we are very pleased with the end result. I would not hesitate to call Sterling again.